About Us

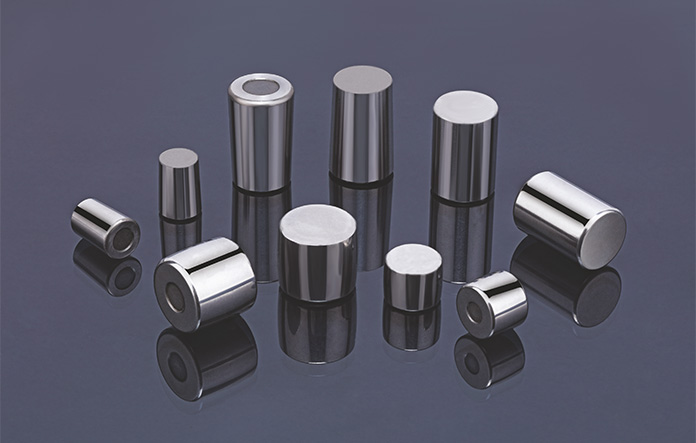

Meet The Bearings: The Core Components Powering Precision Engineering

SINCE 2000

Behind every great machine is a greater bearing. Whether you need strength, speed, flexibility, or innovation — our lineup has your back.

Read More0

Years of

Pro Experience

Pro Experience

Precision

Reliability

Innovation

Performance

Manufacturing Expertise

Durability

Performance

Timely Delivery

Services

Showcasing excellence products portfolio

our products

Our success stories

Our Process

The process behind our success bearing products

At DHJ Engitech, every component is designed to move industry forward — with exacting precision, dependable performance, and measurable progress.

Read Morestep

Precision

We engineer every component with microscopic accuracy to ensure flawless motion. Every bearing is crafted to deliver consistency, balance, and reliability at its core.

01

step

Performance

Built to endure pressure, speed, and time — our designs redefine durability. Each product is tested to perform seamlessly under demanding industrial conditions.

02

step

Progress

Innovation drives every evolution at DHJ Engitech. We continuously advance materials and design to power the next generation of machinery.